How does it work?

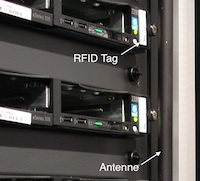

RFID tags reveal not only what is in the rack, but also how much space is occupied and where.

Cavea RFID DCIM is an innovative UHF RFID solution for IT rack inventorying and capacity planning.

The EPCglobal Class 1 Gen2 standard for UHF RFID brings considerable improvements and flexibility with regard to read range and bulk read performance. The Cavea Dynamic IT Asset Monitoring covers read distances from a few centimeters to a few meters based on the same LOCFIELD® UHF antenna technology. It therefore permits seamless combinations of e.g. IT operations and logistics and requires only one quite simple RFID antenna per rack.

The key concept of the solution is using off-the-shelf UHF RFID tags simultaneously in two different ways:

- For identification of RFID tagged components within the IT rack.

- As "sensor" for detecting empty and occupied slots within the rack.

A sophisticated procedure in combination with a simple, cost-effective implementation yields completely new possibilities for IT asset and infrastructure management in almost real-time. This can be achieved by introducing different logical tag types.

Rack Tags

Rack Tags identify the IT rack itself and contain the exact location. This provides the exact physical location data automatically with each inventory cycle.

Position Tags

Component Tags

Component Tags store the individual EPCs of the objects, e.g. servers, routers, USV, console, etc. mounted in the rack. Due to the standard format of the EPC, data can be queried and accessed by a wide range of corporate applications and systems worldwide.

Control Tags

Control Tags are used for labeling additional components in order to implement sophisticated functionality. Simply by tagging blind plates, one can monitor exactly when a slot is opened or closed, e.g. for monitoring work-flows or ensuring perfect cooling air flow. The size of the blind plate is also a useful indicator of sequential free rack space.